Fabricante profissional de brinquedos em PVC: Seu parceiro abrangente do conceito ao produto final

Solução de personalização de brinquedos em PVC completa

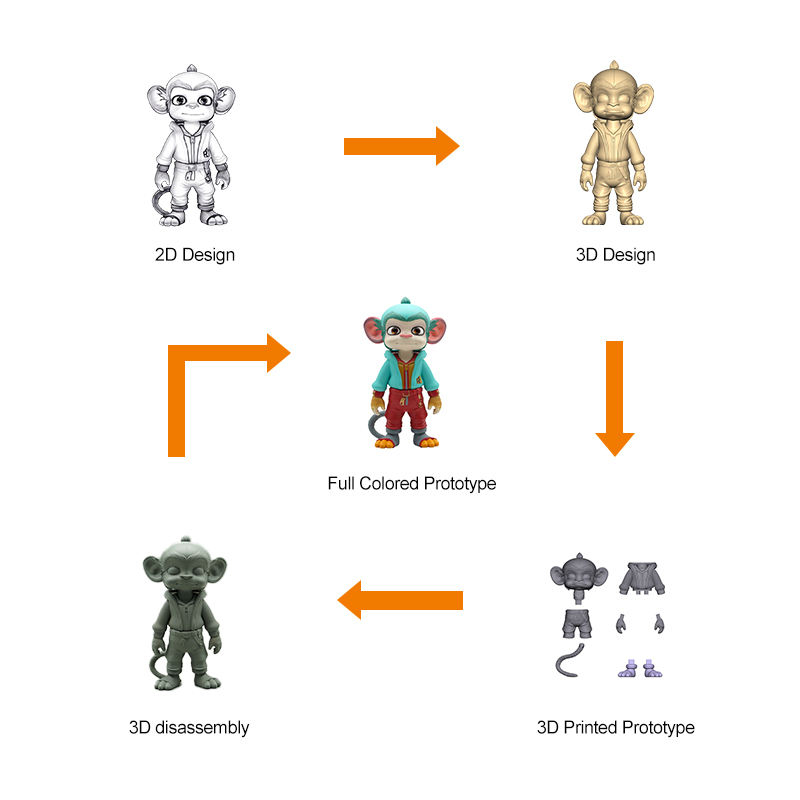

Como fabricante profissional de brinquedos em PVC, entendemos profundamente cada etapa necessária para transformar uma ideia simples em um belo produto final. Oferecemos serviços verdadeiramente personalizados desde o início, atuando como sua equipe estendida de P&D e produção. Todo o processo começa com seu conceito criativo, e nossa equipe trabalhará em estreita colaboração com você para conduzir uma análise de viabilidade. Em seguida, designers profissionais e modeladores 3D transformarão seus esboços ou descrições vagas em dados 3D precisos e prontos para moldagem. Depois de confirmar o modelo 3D, nossa equipe de engenharia iniciará o projeto e desenvolvimento do molde, selecionando simultaneamente materiais e combinando cores. Entrando na fase de produção, nossos rigorosos processos de controle de qualidade são implementados em cada etapa, desde a moldagem por injeção até a pintura, montagem e embalagem, garantindo que o produto final que você recebe corresponda perfeitamente à sua visão inicial, proporcionando uma solução completa e verdadeiramente livre de preocupações.

Especificações principais do produto

A tabela a seguir detalha as principais especificações do produto que oferecemos como fabricante profissional de brinquedos em PVC, demonstrando claramente o escopo de nossas capacidades de serviço.

| Categoria de parâmetro |

Descrição específica |

| Materiais principais |

PVC (cloreto de polivinila) ecologicamente correto, ABS, TPR (componentes de borracha macia) |

| Processo de produção |

Moldagem por injeção, processamento de vinil, pintura manual, impressão por tampografia, serigrafia |

| Tipo de produto |

Figuras de anime, estatuetas de caixa cega, modelos de desenhos animados, chaveiros, brindes promocionais, brinquedos educativos |

| Ponto de partida da personalização |

Quantidade mínima de pedido: 3.000 peças; pedidos em massa são bem-vindos |

| Suporte de cores |

Suporta correspondência precisa de cores Pantone e fornece reprodução de cores de alta fidelidade |

| Vida útil do molde |

Feitos de aço de alta qualidade, os moldes podem suportar centenas de milhares de ciclos de produção e são altamente duráveis |

| Prazo de produção |

Prazo de entrega da amostra: 7-10 dias; Prazo de entrega da produção em larga escala: 25-30 dias (dependendo da complexidade do pedido) |

| Serviço de amostra |

Serviço de prova física fornecido para garantir que a qualidade em larga escala corresponda à amostra |

| Embalagem |

As opções de embalagem personalizáveis incluem embalagens blister, caixas coloridas, caixas com janela e caixas de exibição. |

| Termos comerciais |

Suporta vários métodos comerciais, incluindo FOB, CIF e EXW, com um conjunto completo de documentos de exportação fornecidos. |

Oficina de moldes interna e linha de produção avançada

Entendemos que controlar os principais processos de fabricação é crucial para a qualidade e eficiência. Portanto, como um fabricante veterano de brinquedos em PVC, investimos pesadamente em nossa própria oficina de moldes e linhas de produção totalmente modernas. Isso significa que todo o processo de fabricação de moldes, desde o projeto do molde, usinagem CNC, EDM, até o polimento e montagem, é concluído inteiramente em nossas instalações. Este modelo verticalmente integrado oferece duas vantagens principais: Primeiro, eficiência superior. Eliminar a dependência de oficinas de moldes externas permite uma comunicação interna perfeita, reduzindo significativamente o tempo de desenvolvimento e modificação do molde e garantindo o progresso rápido do projeto. Segundo, controle de qualidade final. Monitoramos direta e rigorosamente a precisão do molde, a qualidade do aço e cada parâmetro no processo de produção, garantindo fundamentalmente a estabilidade estrutural e a expressão detalhada de cada produto de brinquedo em PVC.

Vinte anos de experiência no setor

Na indústria de fabricação de brinquedos altamente competitiva, a experiência é um trunfo inestimável. Como um fabricante de brinquedos em PVC com 20 anos de experiência profissional em produção, acumulamos profunda experiência técnica e sabedoria do setor. Este não é apenas um número; representa nossa experiência através de várias rodadas de mudanças na indústria e atualizações de padrões, resultando em um profundo entendimento de tudo, desde propriedades de materiais e processos de produção até tendências de mercado. Entendemos como ajustar as proporções dos materiais de PVC para obter a suavidade, dureza e tenacidade ideais; somos proficientes em lidar com juntas complexas e expressões faciais sutis; e entendemos como equilibrar segurança e durabilidade, garantindo a estética. Essa experiência acumulada nos permite prever e mitigar possíveis problemas de produção, garantindo que cada brinquedo em PVC que fabricamos para você seja uma cristalização de qualidade e artesanato.

Certificações autorizadas: A pedra angular da qualidade e da parceria

Como um fabricante de brinquedos em PVC com parcerias de longa data com mercados internacionais e marcas renomadas, nosso extenso portfólio de certificações autorizadas é um testemunho sólido de nosso compromisso e capacidades. Somos totalmente certificados ISO9001, garantindo controle padronizado e sistemático em todo o nosso processo, desde a aquisição de matérias-primas até o envio do produto final. Mais importante, passamos com sucesso nas rigorosas inspeções de fábrica e auditorias do sistema de qualidade dos principais detentores de IP globais, como Disney e NBCU. Essas certificações não apenas garantem o acesso ao mercado internacional, mas também servem como um forte endosso de nossa capacidade de realizar projetos derivados de IP de ponta e nosso compromisso inabalável com a segurança e qualidade do produto. Escolher-nos significa que seu projeto operará sob um sistema que adere a um dos mais altos padrões globais, proporcionando tranquilidade.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!